LA NOSTRA STORIA

OUR HISTORY

UNSERE GESCHICHTE

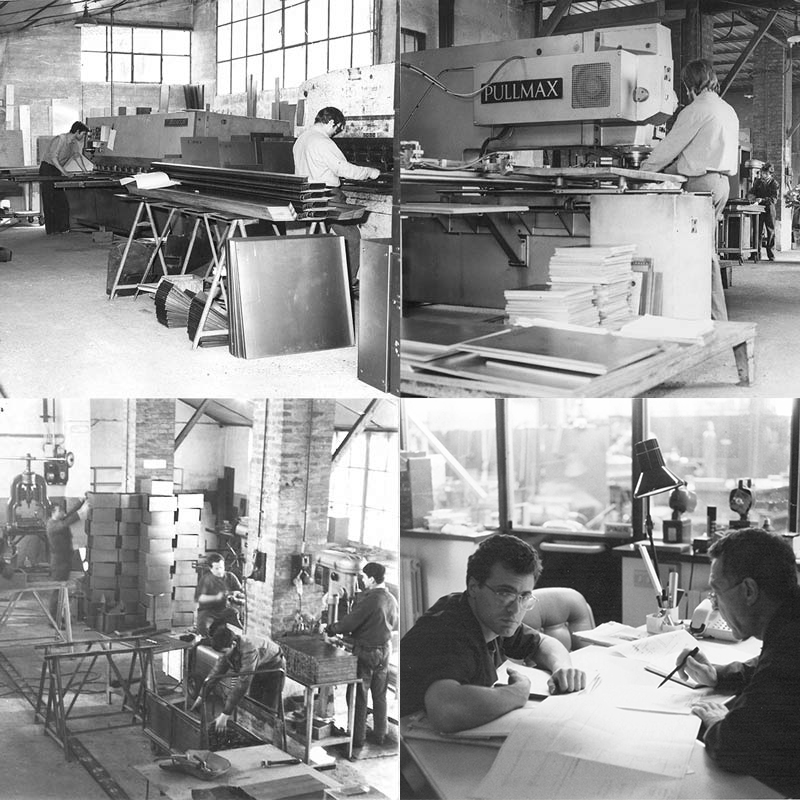

CIM s.r.l. (Costruzione Impianti Meccanici) nasce nel 1961 grazie all’ingegno di Eugenio Moriggi che attrezza un cascinale presso Rovagnasco, una piccola frazione di Segrate in provincia di Milano, al fine di garantire gli spazi necessari per lavori di carpenteria leggera. Da sempre a conduzione famigliare, l’azienda cresce nel tempo trasformandosi da un’attività prettamente artigianale a una realtà industriale focalizzata sulla continua evoluzione.

Nel 1980 CIM s.r.l. si sposta a Vignate e acquistata una macchina per taglio laser COHERENT da 500 Watt di potenza, all’epoca uno dei macchinari a taglio laser tra i più performanti in Italia. La crescita dell’azienda si concentra nel mantenimento di un parco macchine sempre attuale e all’avanguardia, segnata nel 1987 dall’acquisto di una macchina punzonatrice BEHRENS 1000 Watt con generatore laser ROFIN-SINAR che nel 1989 viene affiancata da una seconda macchina punzonatrice combinata BEHRENS con generatore laser ROFIN-SINAR 1250 Watt, sostituito poi con uno da 2000 Watt.

Sul finire degli anni ’80 l’acquisto di uno dei primi robot di saldatura sul territorio italiano e la successiva implementazione di altre 3 postazioni di saldatura e lucidatura robotizzata, tutti in partnership con FANUC Italia, hanno permesso all’azienda l’automazione necessaria per trasformarsi in una moderna realtà industriale.

Nel 2006 l’acquisto della macchina laser punzonatrice giapponese AMADA EML3610NT dotata di carico e scarico lamiera automatizzato, ha segnato un importante traguardo nell’ innovazione aziendale che ha poi permesso nel 2016 il trasferimento nell’attuale sito produttivo di Treviglio, dove oggi impiega 16 dipendenti.

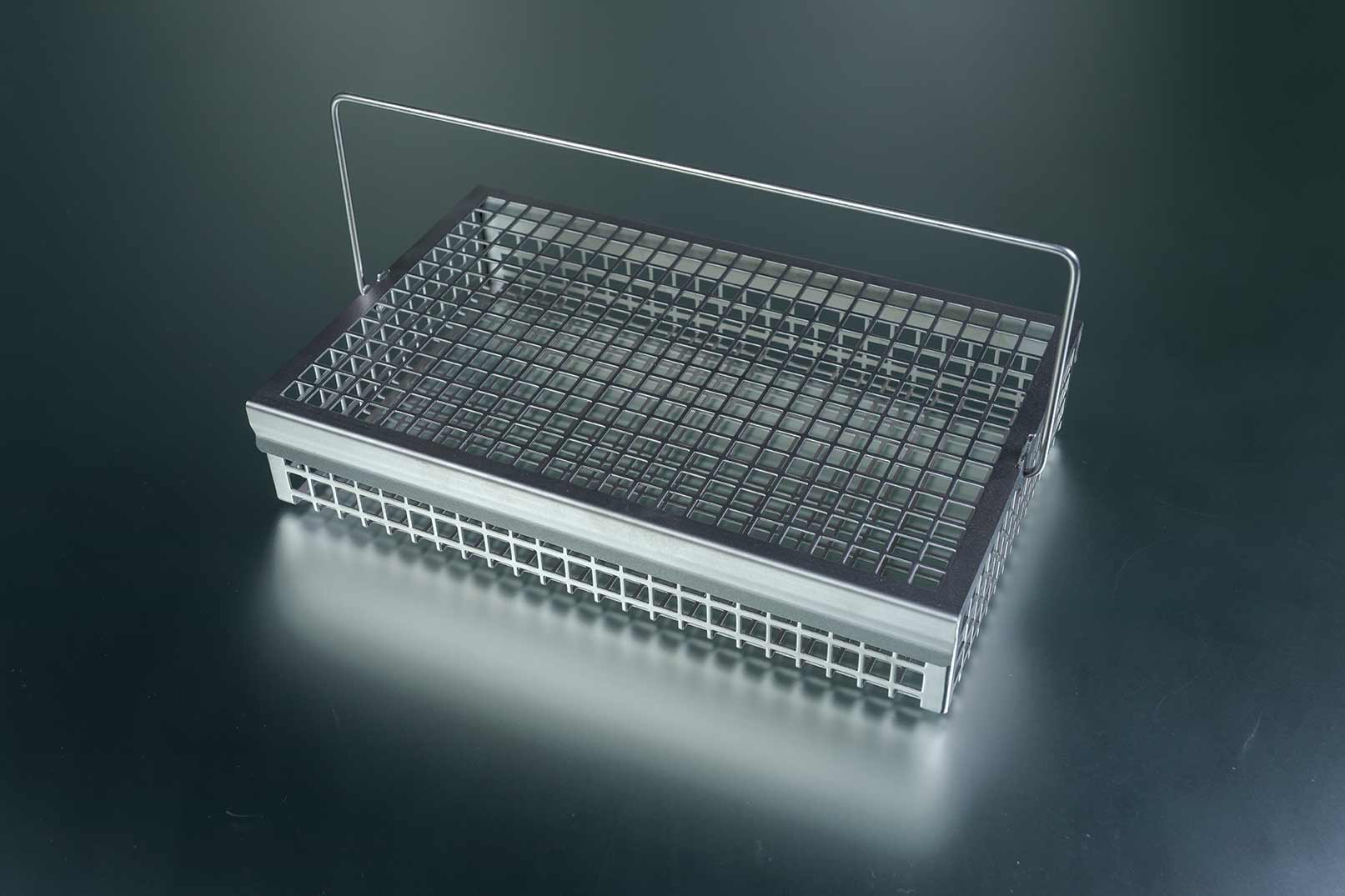

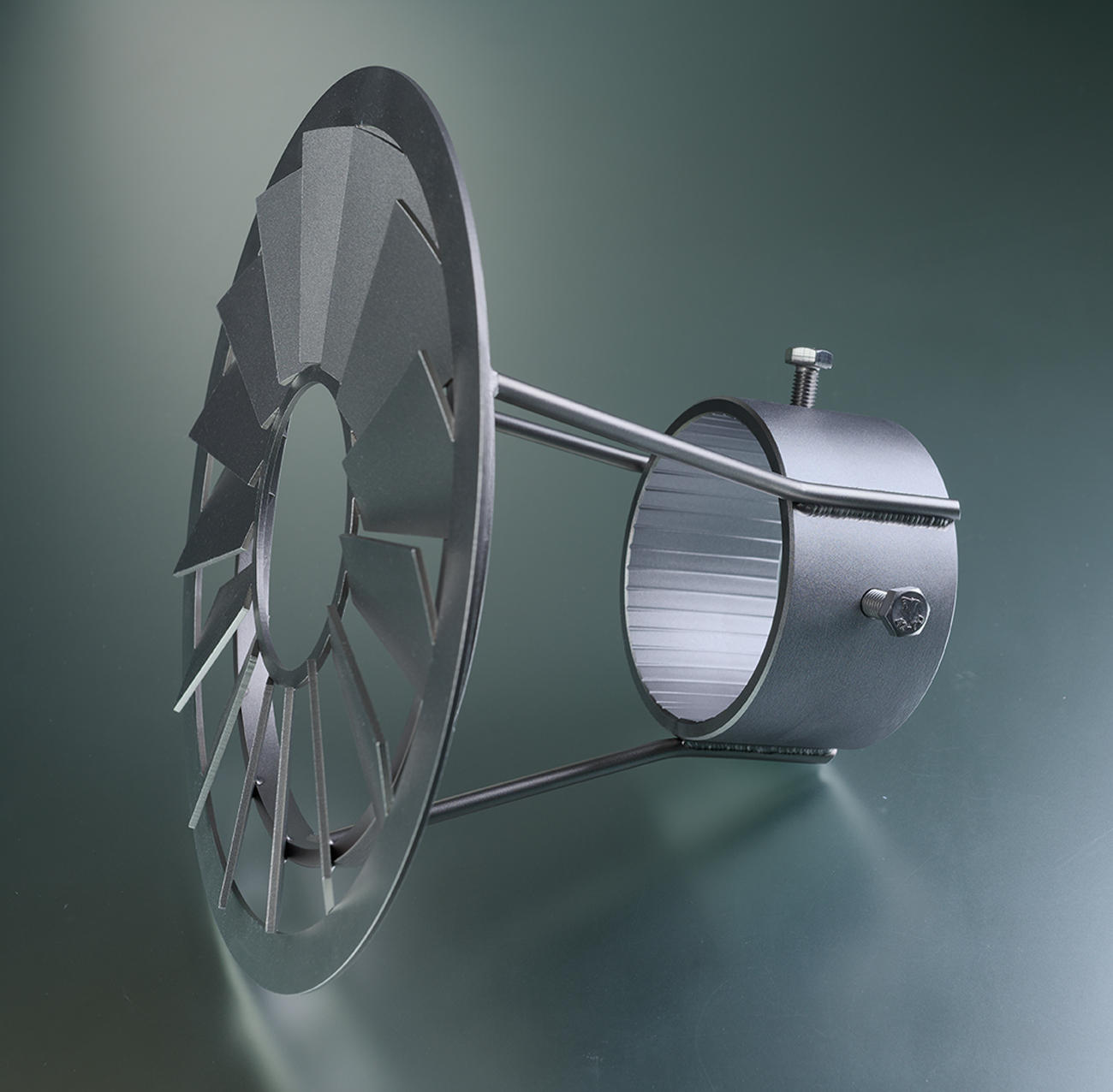

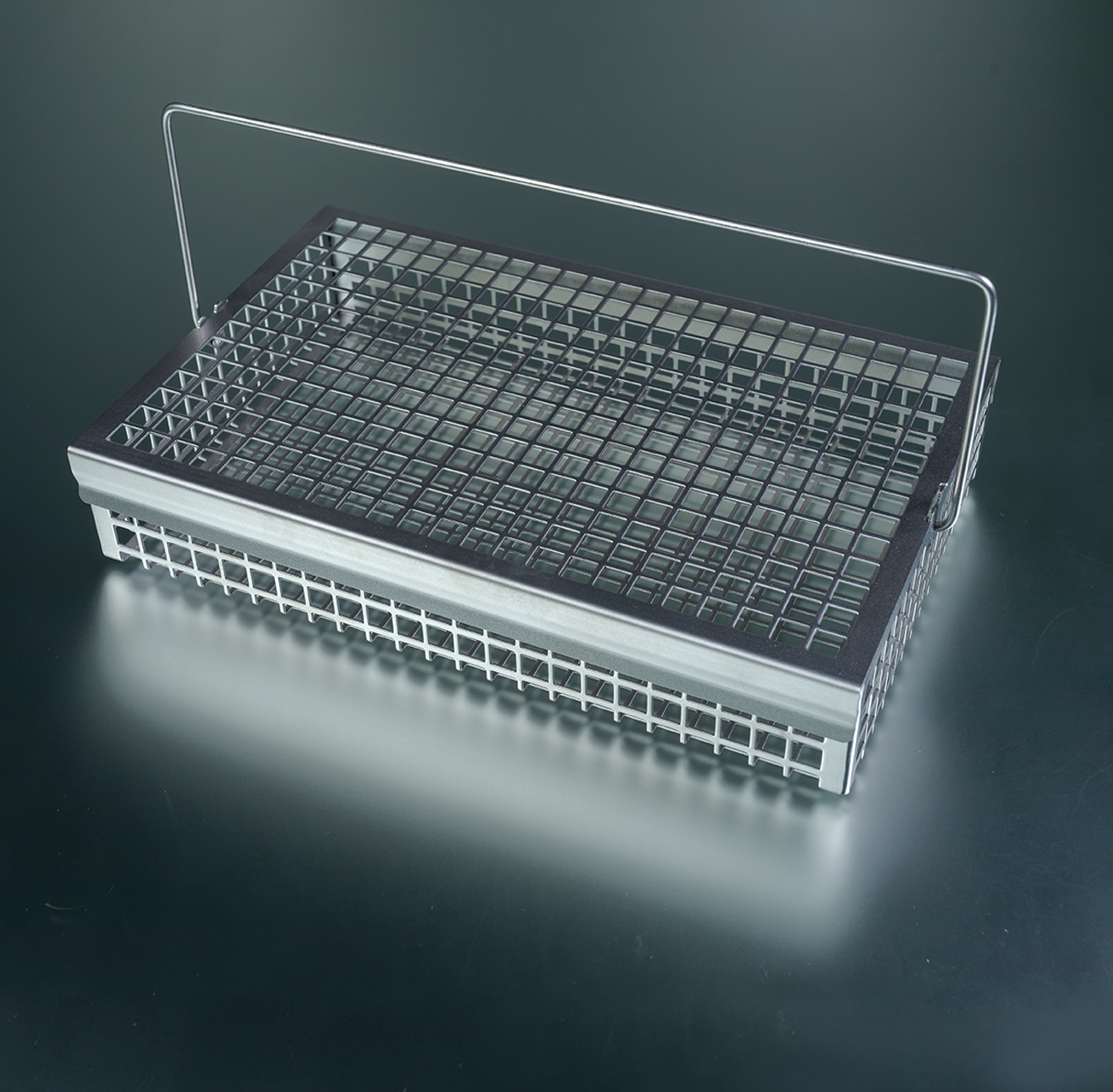

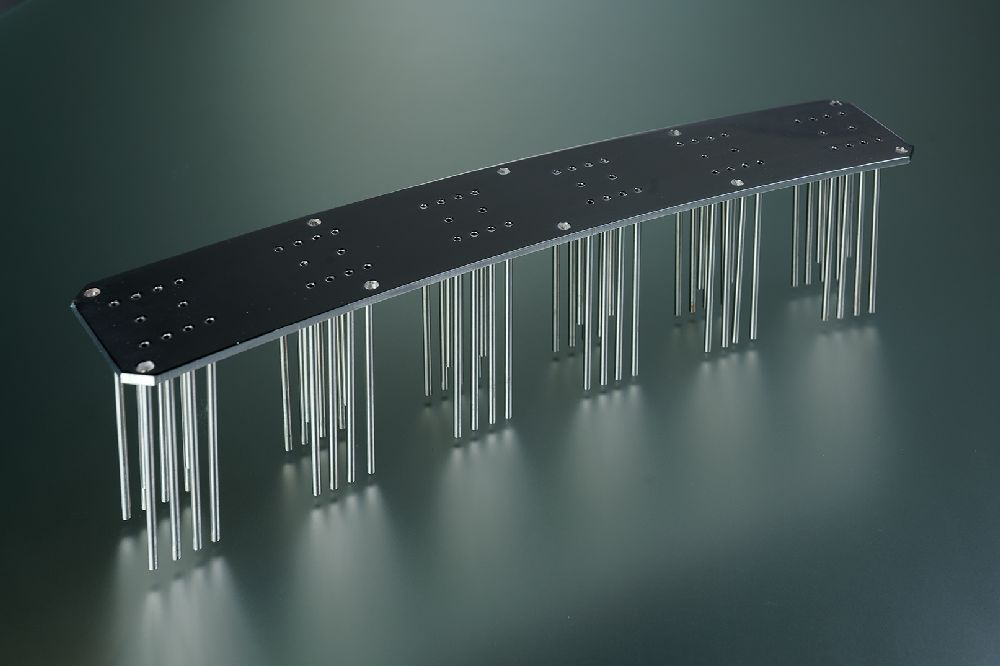

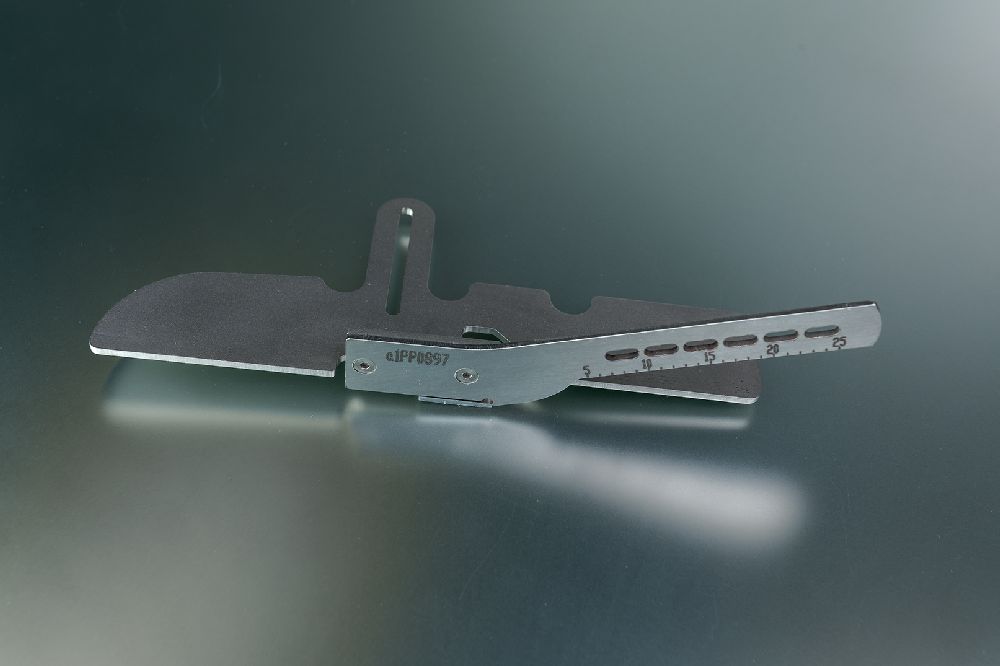

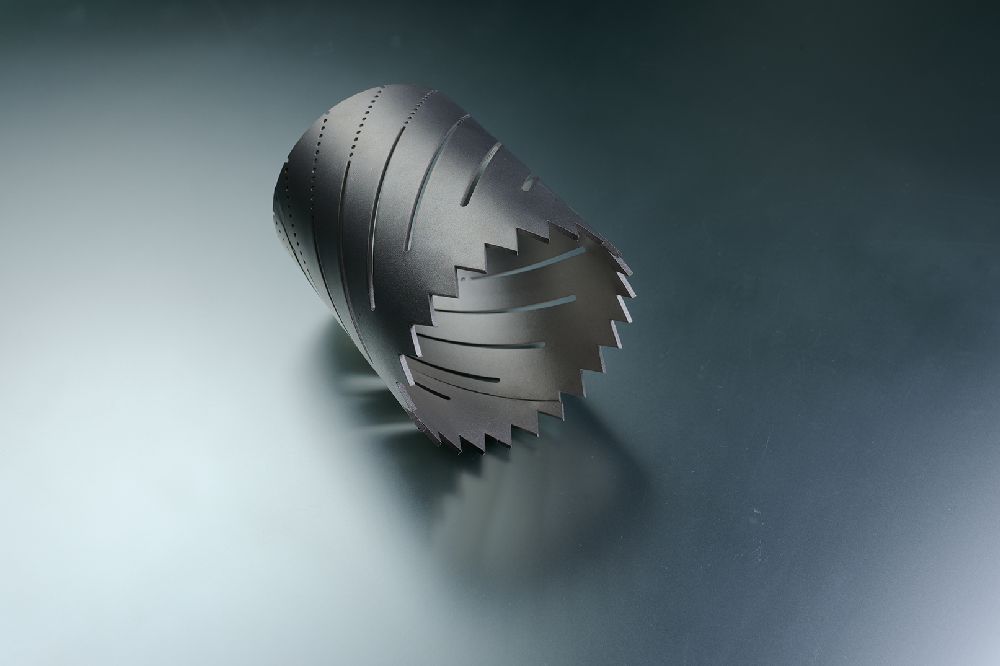

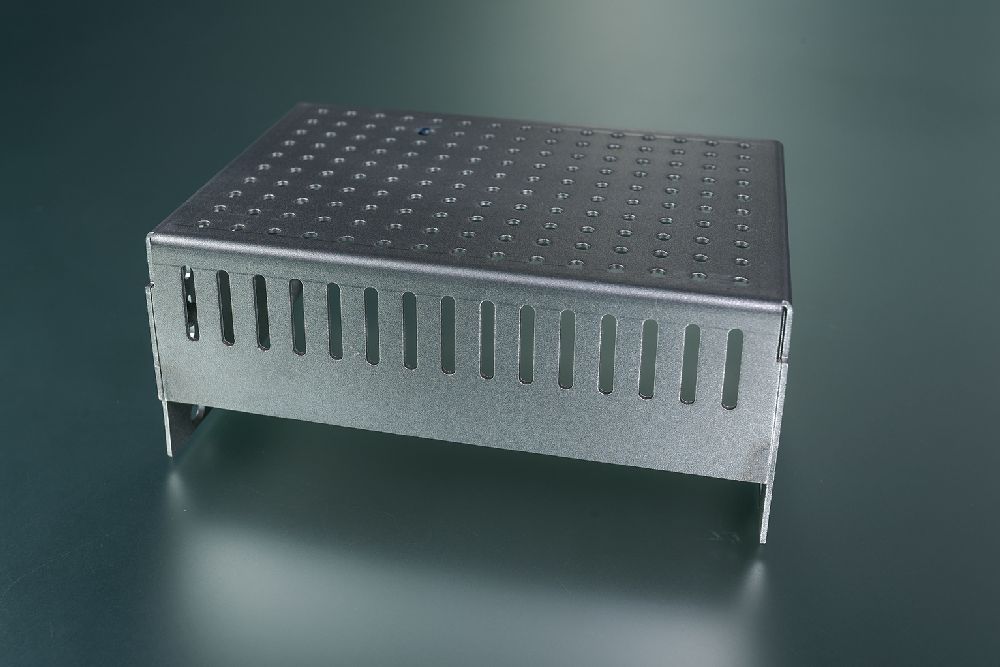

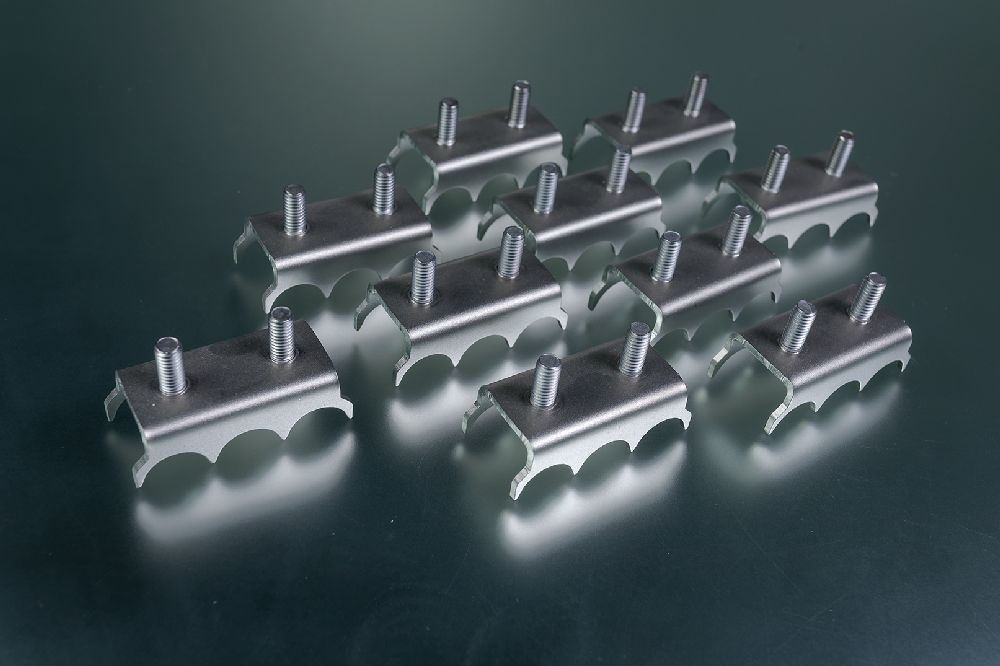

CIM s.r.l. occupa un’area di 3200 m² completamente dedicati a lavorazioni di carpenteria leggera per la realizzazione di manufatti di ogni tipo, che vengono studiati e realizzati attraverso un processo produttivo completo, dalla progettazione alle lavorazioni meccaniche di taglio laser, piegatura e saldatura, fino all’imballaggio e alla consegna.

La nuova generazione a conduzione dell’azienda ha portato innovativi concetti per gestire l’operato quotidiano, come il nuovo programma gestionale per ottimizzare la pianificazione delle attività - indispensabile per una realtà data driven - e il recente servizio Whatsapp attivato per essere più vicini ai clienti.

La qualità è uno degli obiettivi principali e caratteristica imprescindibile del lavoro di CIM s.r.l.. Per questo motivo il processo produttivo è sottoposto a continuo aggiornamento: l’ultimo arrivato è il magazzino automatico UMAG accuratamente gestito grazie a un carrello elevatore automatizzato comandato direttamente da postazione computerizzata e una baia semovente per prelievo dei pacchi di lamiera comodo e veloce.

Eseguiamo lavorazioni sui seguenti materiali: ferro, acciaio, inox, bronzo, alluminio, ghisa, materiale non ferroso, materiale plastico.

CIM s.r.l. (Costruzione Impianti Meccanici – "Mechanical Equipment Construction") was established in 1961after the enterprising Eugenio Moriggi fitted out a farmhouse in Rovagnasco, a small village near Milan, for light carpentry work. In the course of the years, the company, which continues to be family-run, has grown from an artisanal business to an industrial firm focused on continual evolution.

In 1980, CIM s.r.l. moved to nearby Vignate and purchased a COHERENT 500-watt laser-cutting machine, at thetime one of the most advanced machines of its kind in Italy. A significant driver of the company’s growth has always been its range of the latest, state-of-the-art machines. In 1987, it purchased one of the first BEHRENS 1000-watt punching machines with a ROFIN-SINAR laser generator. In 1989, it was joined by a second BEHRENS combined punching machine with a 1250-watt ROFIN-SINAR laser generator, soon to be replaced by a 2000-watt model.

The late 1980s saw the company buy one of the first welding robots in Italy. This was followed by a further three robotic welding and polishing points in partnership with FANUC Italia, and meant that the firm had the levels of automation required for its transformation into a fully fledged modern industrial company.

In 2006, the purchase of the Japanese AMADA EML3610NT laser-punching machine, featuring automatic sheet loading and unloading, marked a significant step forward in the company’s evolution, and led to its 2016 move to the current production site in Treviglio, where 16 employees work.

CIM’s facilities cover an area of 3,200 m² dedicated to light carpentry and metalworking for making a whole host of products, which are the result of a complete production process – from design, mechanical laser- cutting processing and bending and welding through to packaging and delivery.

The new generation of the family leading the business has brought in innovative new processes to manage daily operations. Examples include a new management programme to optimise planning, which has shifted the company towards a data-driven approach, and a recent WhatsApp service launched to provide better customer service.

Quality is a central objective and a core characteristic of CIM’s work. It is why production processes at the company are constantly updated: the most recent examples of this focus in action are an automated for klift truck operated directly from a computerised position to optimally mange the warehouse, and a self-moving bay for rapid and convenient sheet-metal pack extraction.

We work with the following materials: iron, steel, stainless steel, aluminium, cast iron, non-ferrous materials, plastic material.

CIM S.r.l. (Costruzione Impianti Meccanici) wurde 1961 auf Initiative von Eugenio Moriggi gegründet. Er rüstete ein Bauernhaus in der Nähe von Rovagnasco, einem kleinen Ortsteil von Segrate in der Provinz Mailand um, um den notwendigen Platz für leichte Metallbauarbeiten zu schaffen. Das stets durch die Familie geführte Unternehmen wuchs im Laufe der Zeit und verwandelte sich von einem reinen Handwerksbetrieb zu einem Industrieunternehmen, das auf eine kontinuierliche Entwicklung ausgerichtet ist.

1980 übersiedelte CIM nach Vignate und erwarb eine COHERENT Laserschneidmaschine mit 500 Watt Leistung. Zum damaligen Zeitpunkt eine der leistungsstärksten Laserschneidmaschinen in Italien. Das Unternehmenswachstum konzentriert sich auf die Erhaltung eines stets aktuellen und hochmodernen Maschinenparks. Prägend war 1987 der Kauf einer der ersten BEHRENS Stanzmaschinen mit 1000 Watt mitdem ROFIN-SINAR Lasergenerator, zu der 1989 eine zweite kombinierte BEHRENS Stanzmaschine mit ROFIN-SINAR Lasergenerator mit 1250 Watt hinzukam, die später durch eine mit 2000 Watt ersetzt wurde.

Gegen Ende der 80er Jahre gestatteten der Kauf eines der ersten Schweißroboter auf italienischem Staatsgebiet und die anschließende Implementierung weiterer 3 Roboter-Schweiß- und -Polierstationen,alle in Partnerschaft mit FANUC Italia, dem Unternehmen die notwendige Automation, um sich in einen modernen Industriebetrieb zu verwandeln.

2006 markierte der Kauf der japanischen Laserstanzmaschine AMADA EML3610NT mit automatisierter Blechzuführung und -entladung einen wichtigen Meilenstein in der Unternehmensinnovation. Dies ermöglichte 2016 den Umzug an den derzeitigen Produktionsstandort in Treviglio, wo heute 16 Mitarbeiter beschäftigt werden.

CIM S.r.l. nimmt eine Fläche von 3200 m² ein, die vollständig dem Leichtmetallbau für die Fertigung vielfältigster Produkte gewidmet ist. Diese werden über einen umfassenden Produktionsprozess entwickelt und hergestellt, der von der Planung über das mechanische Laserschneiden, Biegen und Schweißen bis hinzur Verpackung und Lieferung reicht.

Die neue Generation in der Unternehmensführung brachte innovative Konzepte zur Verwaltung destäglichen Betriebs ein. Als Beispiel zu erwähnen sind das neue Managementprogramm zur Optimierung der Planung der Aktivitäten, welches die Entwicklung des Unternehmens zu einem datengesteuerten Unternehmen fördert, sowie der kürzlich aktivierte WhatsApp-Dienst, um näher am Kunden zu sein.

Qualität ist eines der Hauptziele und unverzichtbaren Merkmale der Arbeit der CIM S.r.l. Aus diesem Grund wird der Produktionsprozess ständig aktualisiert: Unsere letzte Neuerung ist das sorgfältig verwaltete Lager mit einem automatisierten Gabelstapler, der direkt von einer computergesteuerten Station aus gesteuert wird, und einer selbstfahrenden Ladebucht für die bequeme und schnelle Entnahme von Blechpaketen.

Wir führen Bearbeitungen an folgenden Werkstoffen aus:

Eisen, Stahl, Edelstahl, Bronze, Aluminium, Gusseisen, Nichteisenwerkstoffe und Kunststoffmaterial.